Lab Links

Projects

Participants

Publications

Collaborators

Alumni

Links

Lead Investigators

Paul Dawson

prd5@cornell.edu

Matt Miller

mpm4@cornell.edu

Contact Us: webadministrator

The focus of our research in the Deformation Processes

Laboratory is on quantifying our understanding of the

link between the structure of engineering materials and

their performance in design applications. Our work

includes the development of both experimental and simulation

techniques, with special attention to coordinating the

two to best reach our objectives.

We work primarily on polyphase engineering alloys that

have application as structural materials in airframes,

ships, automobiles and engines. Critical properties, ranging

from stiffness to strength to failure, stem from the crystalline

structure of these alloys. Establishing a quantitative

connection between the structural features at this scale

and the macroscopic properties is vital to most effectively

using them.

Our methodologies attempt to build these connections.

The focus of our research in the Deformation Processes

Laboratory is on quantifying our understanding of the

link between the structure of engineering materials and

their performance in design applications. Our work

includes the development of both experimental and simulation

techniques, with special attention to coordinating the

two to best reach our objectives.

We work primarily on polyphase engineering alloys that

have application as structural materials in airframes,

ships, automobiles and engines. Critical properties, ranging

from stiffness to strength to failure, stem from the crystalline

structure of these alloys. Establishing a quantitative

connection between the structural features at this scale

and the macroscopic properties is vital to most effectively

using them.

Our methodologies attempt to build these connections.

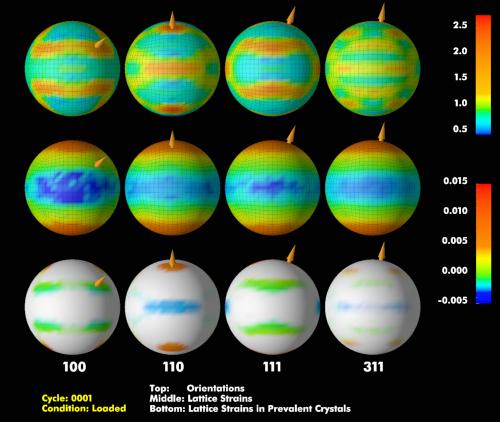

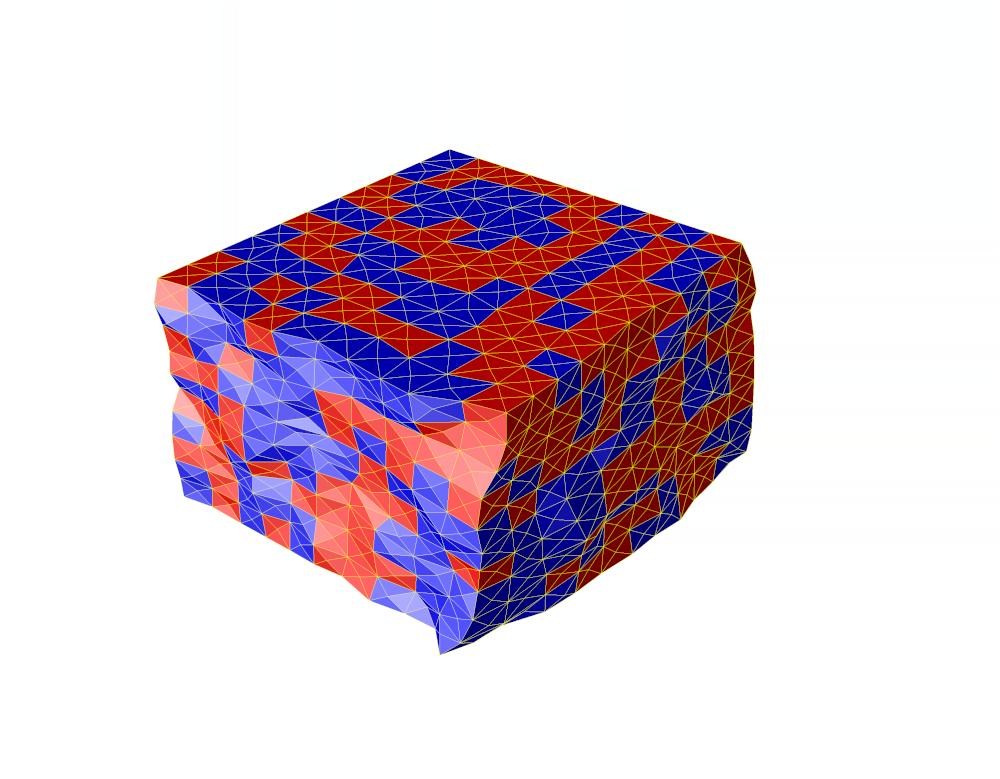

The modeling tools we are developing include ones to

represent the material structure and to simulate the

mechanical response of samples of the material to both

static and cyclic loading. We concentrate on finite element

methods that explicitly represent the crystalline structure

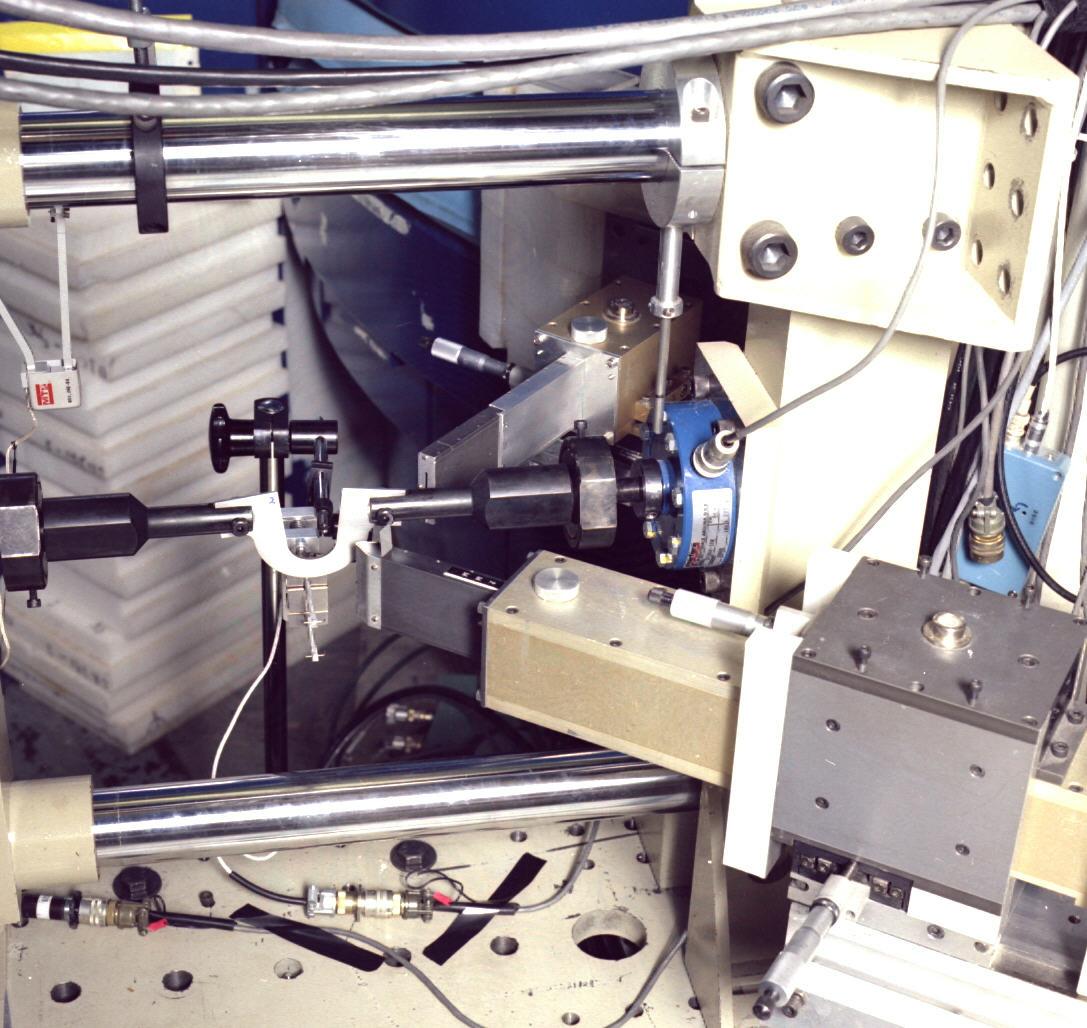

and compute properties from it. The experimental methods

under development involve the use of x ray and neutron diffraction

as a means to measure responses at the crystal level.

Mechanical loading is applied in situ so that response are

interrogated while the deformation processes are ongoing.

The ability to both model materials from the crystal scale

and to measure their behaviors at the corresponding level

provide unique opportunities to advance our understanding

of the relation between properties and structure.

We also apply our simulation and experimental tools to several forming processes. Structural alterations can be the intended outcome of processing or can be the inevitable result of processes carried out for other reasons. In either case, processing is a key element in modifying the structure that eventually determines properties. We have been developing methods for analyzing the thermomechanical histories in bulk forming and sheet forming processes. In addition we are particularly interested in solid state joining processes, such as friction stir welding, where the combined influences of high temperature and severe deformation provide major challenges for our tools.

Check out the links on the

sidebar to explore our program:

Check out the links on the

sidebar to explore our program:

Projects: Brief summaries of the major research projects in the lab, with links to pdf reports

Participants: Names and information on the faculty, staff and students involved in the lab

Publications: Bibliography of important papers that resulted from our research

Collaborators: Facilities at Cornell and other research centers that help with our work

Alumni: Previous doctoral students, post-doctoral research associates and visitors to the lab

Links: Information on the graduate student program and student life in Ithaca